Our Services

Innovative Packaging Solutions Tailored to Your Needs

Corrugated Packaging: Strength and Versatility

Corrugated boxes are the backbone of heavy-duty packaging, ideal for transporting appliances, electronic goods, fruits, and vegetables. These boxes are frequently used as bulk shippers, delivering multiple similar products in a single container. The multi-layered structure, consisting of a top and bottom linerboard and a middle corrugating medium, provides unmatched strength and durability. The distinctive wavy shape of the corrugating medium boosts the box’s resistance to bending, making corrugated fiberboard significantly stiffer and more resilient than flat fiberboard of equivalent weight.

Our Product Offerings

we specialize in producing a wide range of corrugated packaging solutions to meet diverse needs:

-

Manufacturing Corrugated Boards: We offer corrugated sheets in various forms, including single face web (2 layers), single wall board (3 layers), double wall board (5 layers), and double wall board (5 layers).

-

Converting Sheets into Boxes: Our advanced converting processes transform corrugated sheets (printed or non-printed) into custom boxes tailored to your specifications. This includes glued, stitched, and die-cut boxes in different styles.

-

Printing Services: We provide high-quality printing on corrugated sheets in multiple colors to enhance your brand’s visibility and appeal.

-

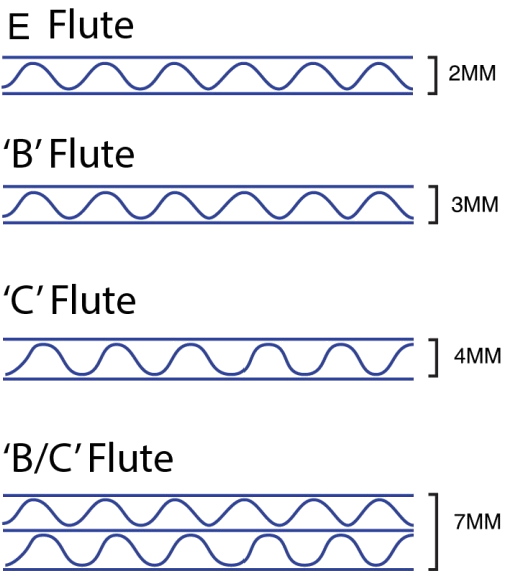

Flute Types and Combinations: We offer a variety of flute types, including B, C, E, and combinations such as B+C and B+E, using both virgin and recycled liner paper to suit different requirements.

Efficient and Recyclable Products

Corrugated carton boxes are the preferred choice for over 80% of industrial packaging due to their numerous advantages:

- Effective Cushioning: Protects contents during transport and handling.

- Lightweight: Reduces shipping costs and is easy to handle.

- Ease of Manufacture and Storage: Simplifies production and saves space.

- Ease of Disposal: Facilitates recycling and waste management.

- No Strapping Needed: Streamlines packaging processes.

- Printing and Advertising Benefits: Enhances marketing opportunities.

- Export Market Essential: Meets international shipping standards.

Corrugated packaging is not only efficient but also environmentally friendly. It is completely recyclable, contributing to sustainability and reducing environmental impact.

FAQ

What materials do you use for your corrugated boxes?

We use high-quality linerboard and corrugating medium, available in both virgin and recycled paper options, to ensure durability and sustainability.

Can you customize the size and design of the boxes?

Yes, we offer fully customizable solutions, including size, design, printing, and box styles, to meet your specific requirements.

What are the benefits of using corrugated packaging?

Corrugated packaging provides excellent protection, is lightweight, easy to manufacture and store, recyclable, and offers great printing and advertising potential.

How does your production process ensure quality?

Our production process includes rigorous quality control at every stage, from initial design to final delivery, ensuring that every product meets the highest standards.

Are your corrugated boxes eco-friendly?

Yes, our corrugated boxes are made from up to 88% recycled materials and are fully recyclable, promoting a sustainable, circular economy.

What types of printing services do you offer?

We offer high-quality printing in several colors on corrugated sheets, enhancing your brand’s visibility and appeal.

What industries do you serve?

We serve a wide range of industries, including electronics, appliances, agriculture, and export markets, providing customized packaging solutions for various needs.

How can I get a quote for a custom packaging solution?

You can contact us via phone at +964 750 871 8888 or email at info@terrapack.net. Our team will work with you to understand your needs and provide a tailored quote.